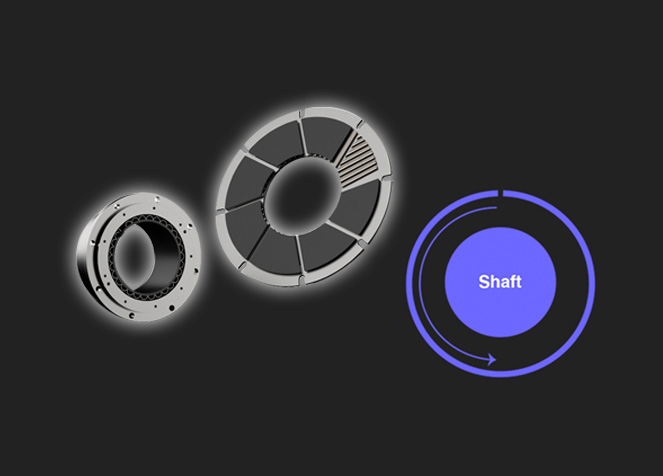

NBW Airfoil Bearing

- Pass 150,000 starts and stops testInternational Patent

(Patent No.# 10-1632356, # 30-0858674) - Turbowin air foil bearings are free of Oil supply device, reduced labor and oil/belt replacement costs compared to other competing companies.

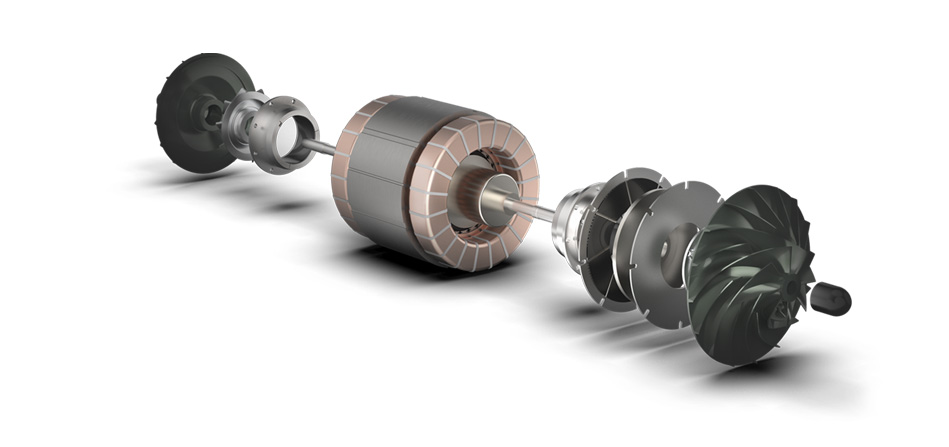

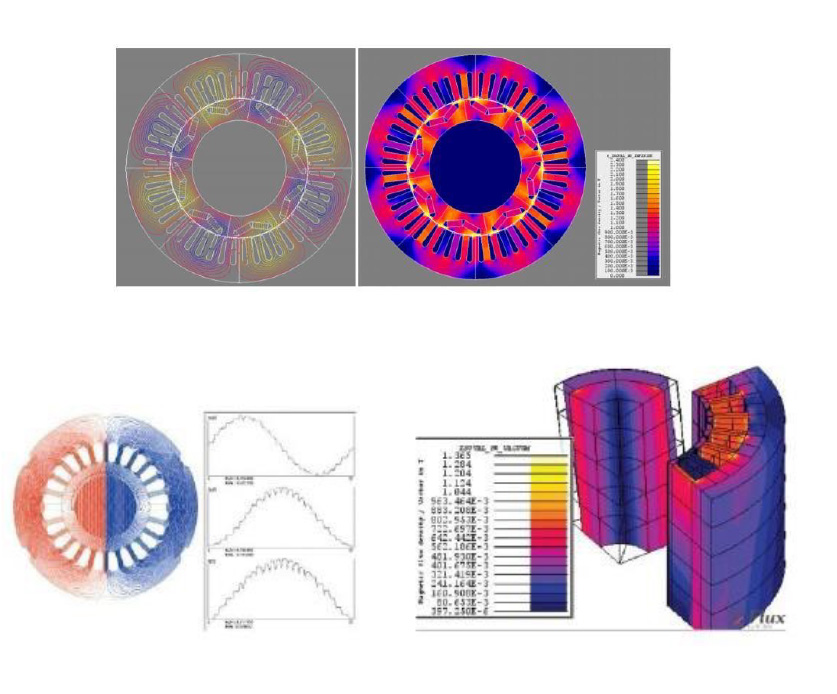

High Efficiency Permanent Magnet Motor

Turbowin's ultra-high-efficiency permanent magnet motors are considered the best in the world, ensuring a high efficiency of over 95%.

This is a result of 20 years of accumulated experience in research and development of turbo technology. Turbowin offers a variety of options from 20,000 RPM to 200,000 RPM, its’ the most efficient ultra-high-speed motor in the world.

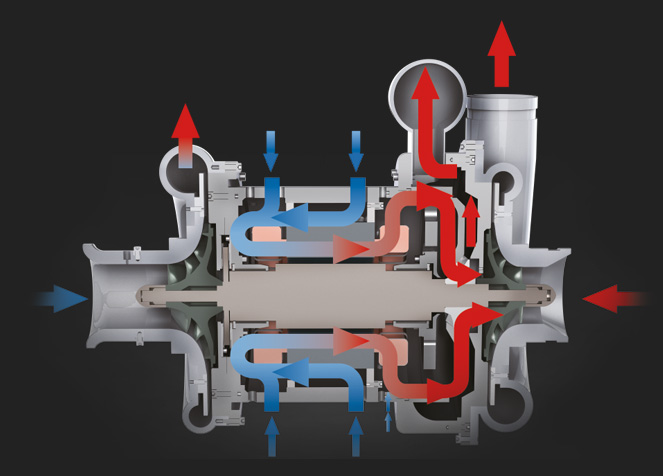

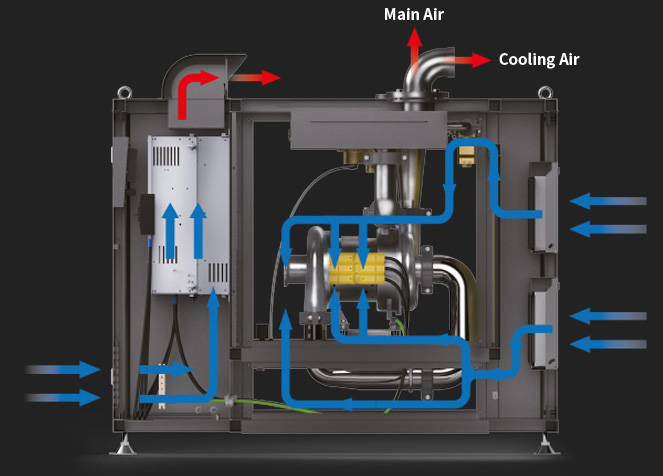

Dual-cooling system

- Based on Turbowin’s patented (Patent #10-1580877, #10-1607492dual cooling system, greatly improve he cooling efficiency.

- (1)First cools the outside of the stator,

- (2)secondary cools the NBW airfoil bearing, winding and rotor.

- Can lowered the temperature with pure air alone and the cooled hot air does not return to the product

- Turbowins’ products are only composed of motors, inverters and controllers, without additional cooling devices such as external cooling fans, so there is no "frequent failure" problem compare with the other brand. It also reflects the excellent research and development spirit of Turbowins’ products.

- Turbowin products can be lowered by at least 10 degrees compared with other brands.

- Improves durability and service life of motor bearings.

- Unique cooling discharge silencers handles heat dissipation and noise, cooling both motor and exhaust when air is drawn in.

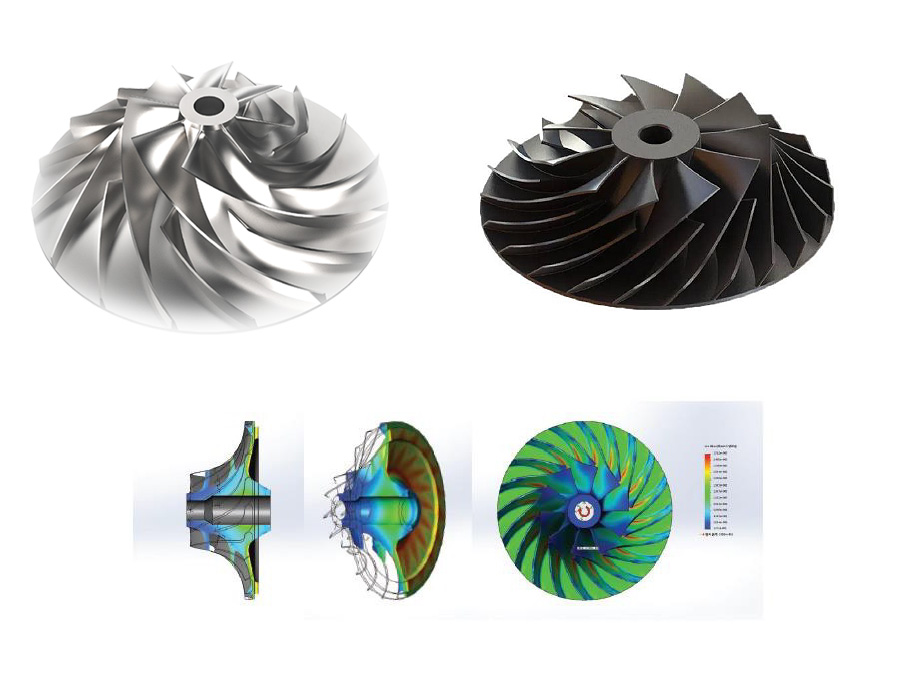

Supersonic impeller

- Turbowin’s all products Supersonic Impeller do not allow an error of 0.001mm.

- By applying Hard Anodizing Coating to the impeller surface to ensure Its stable performance and quality.

- The shape of the impeller with helical wing structure which manufactured by five-axis machine tools is based on its own special design and certificated technology. Compared with competing companies, Turbowin using outsourced OEM impellers, the blade thickness is thicker (more than 2mm) and the specific gravity is less than 1/3, providing customers with the best efficiency.

- Use aluminum alloy (AL7075-T651), stainless steel, titanium, etc. can be applied according to the characteristics of the customer's environment. It has excellent corrosion resistance and chemical resistance by applying hard anodizing coding or special nano coding to the impeller surface.

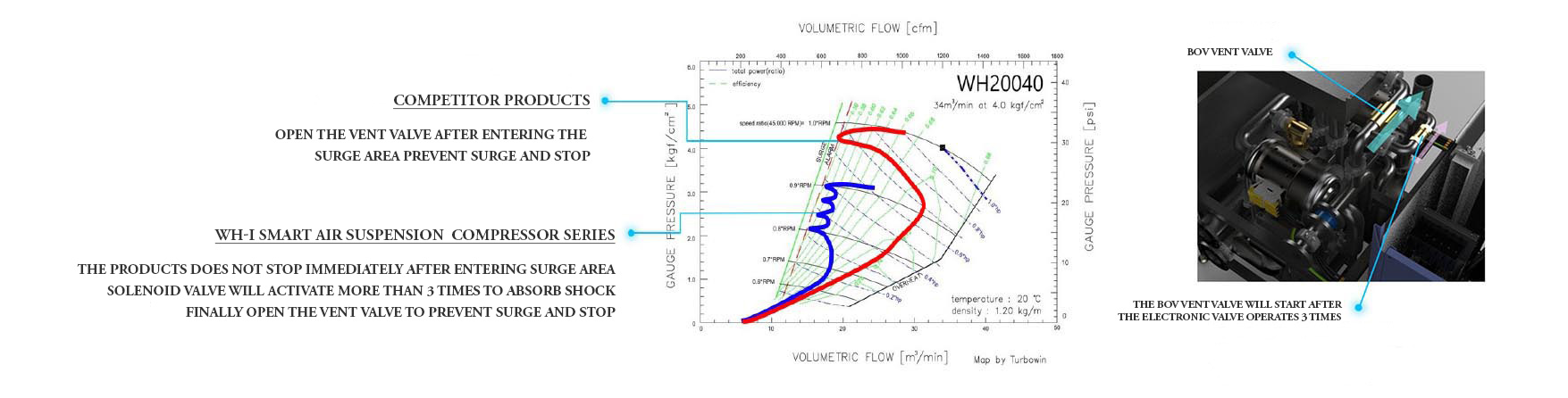

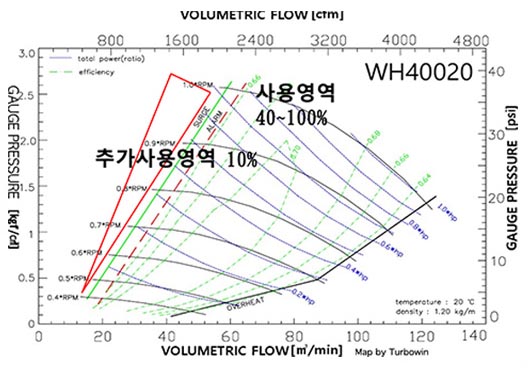

SURGE PROTECTION SYSTEM

- Air suspension Compressor can pass through the surge area where conventional compressors cannot operate, and has 10% more adjustable area.

- Won the patent of air suspension technology (Patent No#10-1991784) used in the surge system. Additional SOL is added to the exhaust system, which can control the overall system more precisely and provide users with additional operating fields.

- With a Sub solenoid valve, When the operating falls under surge area, it will activate three to four times to ensure the product can operate safely, and prevent sudden stop in emergency situations.